Common Production Process of Popular Brand Bridge-Type Center Cutting Machines

I. Introduction

Bridge-type center cutting machines are essential tools in the manufacturing and metalworking industries, known for their precision and versatility. These machines are designed to perform various cutting operations, making them invaluable in sectors such as aerospace, automotive, and general manufacturing. This article aims to provide a comprehensive overview of the common production process of popular brand bridge-type center cutting machines, highlighting the key stages from design to final assembly.

II. Understanding Bridge-Type Center Cutting Machines

A. Description and Functionality

Bridge-type center cutting machines are characterized by their unique design, which features a bridge-like structure that supports the cutting tool. This design allows for enhanced stability and precision during cutting operations. Key components of these machines include the cutting head, worktable, and control system. The cutting head houses the tool, while the worktable holds the material being processed. The control system, often computer numerical control (CNC), allows for precise movements and adjustments.

1. Key Components

Cutting Head: The part of the machine that holds and operates the cutting tool.

Worktable: A flat surface where the material is placed for cutting.

Control System: The interface that allows operators to program and control the machine's movements.

2. Types of Materials Processed

Bridge-type center cutting machines can process a wide range of materials, including metals like aluminum, steel, and titanium, as well as non-metal materials such as plastics and composites. Their versatility makes them suitable for various applications across different industries.

B. Applications in Various Industries

1. Aerospace

In the aerospace industry, precision is paramount. Bridge-type center cutting machines are used to manufacture components such as aircraft frames, engine parts, and landing gear. The ability to cut complex shapes with high accuracy is crucial for ensuring the safety and performance of aircraft.

2. Automotive

The automotive sector relies on these machines for producing parts like chassis, engine components, and body panels. The efficiency and precision of bridge-type center cutting machines contribute to the overall quality and performance of vehicles.

3. General Manufacturing

In general manufacturing, these machines are employed for a variety of tasks, including prototyping, production runs, and custom fabrication. Their adaptability allows manufacturers to meet diverse customer needs.

III. Overview of the Production Process

The production process of bridge-type center cutting machines involves several key stages, each critical to ensuring the final product meets industry standards and customer expectations.

A. Initial Design and Engineering

1. Concept Development

The production process begins with concept development, where engineers and designers collaborate to outline the machine's specifications and features. This stage involves understanding market needs and technological advancements.

2. CAD Modeling

Once the concept is established, computer-aided design (CAD) modeling is employed to create detailed 3D representations of the machine. This allows for precise visualization and adjustments before physical production begins.

3. Prototyping

Prototyping is the next step, where a physical model of the machine is created. This prototype undergoes testing to identify any design flaws or areas for improvement, ensuring that the final product will perform as intended.

B. Material Selection

1. Types of Materials Used

The materials selected for manufacturing bridge-type center cutting machines are crucial for their performance and durability. Common materials include high-strength steel for structural components and specialized alloys for cutting tools.

2. Criteria for Material Selection

Material selection is based on several criteria, including strength, weight, corrosion resistance, and cost. Manufacturers must balance these factors to ensure the machine is both effective and economically viable.

C. Manufacturing Process

The manufacturing process involves several key techniques, including machining and assembly.

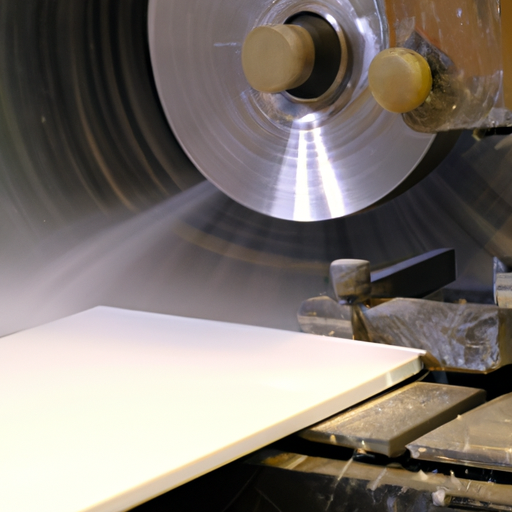

1. Machining

Machining is a critical step in the production of bridge-type center cutting machines. This process can involve both CNC machining and traditional machining techniques.

a. CNC Machining

CNC machining is widely used for its precision and efficiency. Computer-controlled machines perform cutting, drilling, and milling operations with high accuracy, allowing for complex geometries and tight tolerances.

b. Traditional Machining Techniques

While CNC machining is prevalent, traditional techniques such as manual milling and turning are still employed for specific tasks or smaller production runs. These methods can provide flexibility and adaptability in the manufacturing process.

2. Assembly

Once the individual components are machined, they are assembled into the final machine. This stage involves careful alignment and fitting of parts to ensure optimal performance.

a. Component Assembly

Component assembly includes the installation of the cutting head, worktable, and control system. Each part must be securely attached and calibrated to function correctly.

b. Quality Control Measures

Quality control measures are implemented throughout the assembly process to ensure that each machine meets the required specifications. This includes inspections and tests at various stages of assembly.

D. Surface Treatment and Finishing

1. Coating Processes

After assembly, surface treatment is performed to enhance the machine's durability and appearance. Coating processes such as powder coating or anodizing protect against corrosion and wear.

2. Polishing and Finishing Techniques

Finishing techniques, including polishing and grinding, are applied to achieve a smooth surface and improve the machine's aesthetic appeal. These processes also contribute to the machine's overall performance.

IV. Quality Assurance and Testing

A. Importance of Quality Control

Quality assurance is a critical aspect of the production process for bridge-type center cutting machines. Ensuring that each machine meets stringent quality standards is essential for customer satisfaction and safety.

B. Testing Procedures

1. Functional Testing

Functional testing involves running the machine through its operational capabilities to ensure it performs as expected. This includes testing cutting accuracy, speed, and overall functionality.

2. Safety Testing

Safety testing is conducted to verify that the machine complies with industry safety standards. This includes checks for emergency stop functions, electrical safety, and mechanical integrity.

C. Certification and Compliance Standards

Manufacturers must adhere to various certification and compliance standards, such as ISO and CE certifications. These standards ensure that the machines are safe, reliable, and of high quality.

V. Final Assembly and Packaging

A. Final Assembly Process

The final assembly process involves a thorough inspection of the machine to ensure all components are correctly installed and functioning. Any necessary adjustments are made before the machine is prepared for shipping.

B. Packaging Considerations

1. Protection During Shipping

Packaging is crucial to protect the machine during transportation. Manufacturers use custom packaging solutions to prevent damage and ensure that the machine arrives at its destination in perfect condition.

2. Branding and Marketing

Packaging also serves a marketing purpose. Manufacturers often include branding elements and product information to enhance visibility and appeal to customers.

VI. Conclusion

In summary, the production process of popular brand bridge-type center cutting machines involves a series of meticulously planned stages, from initial design and material selection to manufacturing, quality assurance, and final assembly. The importance of quality and innovation in manufacturing cannot be overstated, as these factors directly impact the performance and reliability of the machines. As technology continues to advance, future trends in bridge-type center cutting machine production will likely focus on increased automation, enhanced precision, and sustainable manufacturing practices.

VII. References

A. Industry Standards and Guidelines

- ISO 9001: Quality Management Systems

- CE Marking: European Conformity

B. Relevant Literature and Case Studies

- "Advancements in CNC Machining Technology" - Journal of Manufacturing Science

- "The Role of Precision Cutting in Aerospace Manufacturing" - Aerospace Engineering Review

C. Manufacturer Websites and Technical Resources

- [XYZ Machinery](http://www.xyzmachinery.com)

- [ABC Cutting Tools](http://www.abccuttingtools.com)

This comprehensive overview of the production process for bridge-type center cutting machines highlights the intricate steps involved in creating these essential tools for modern manufacturing. By understanding this process, stakeholders can appreciate the complexity and craftsmanship that goes into each machine, ensuring they meet the high standards required in today's competitive industries.